Concept:

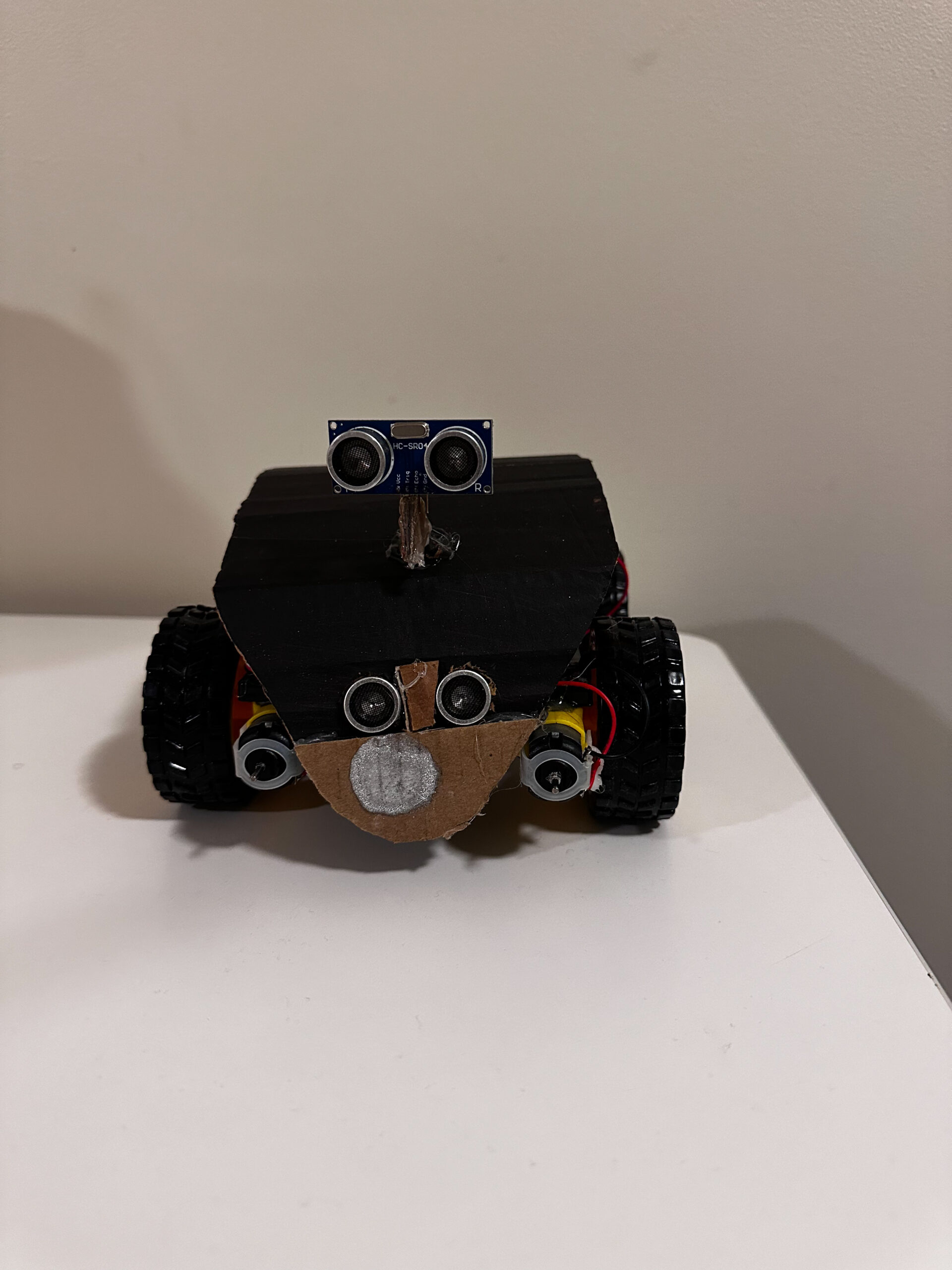

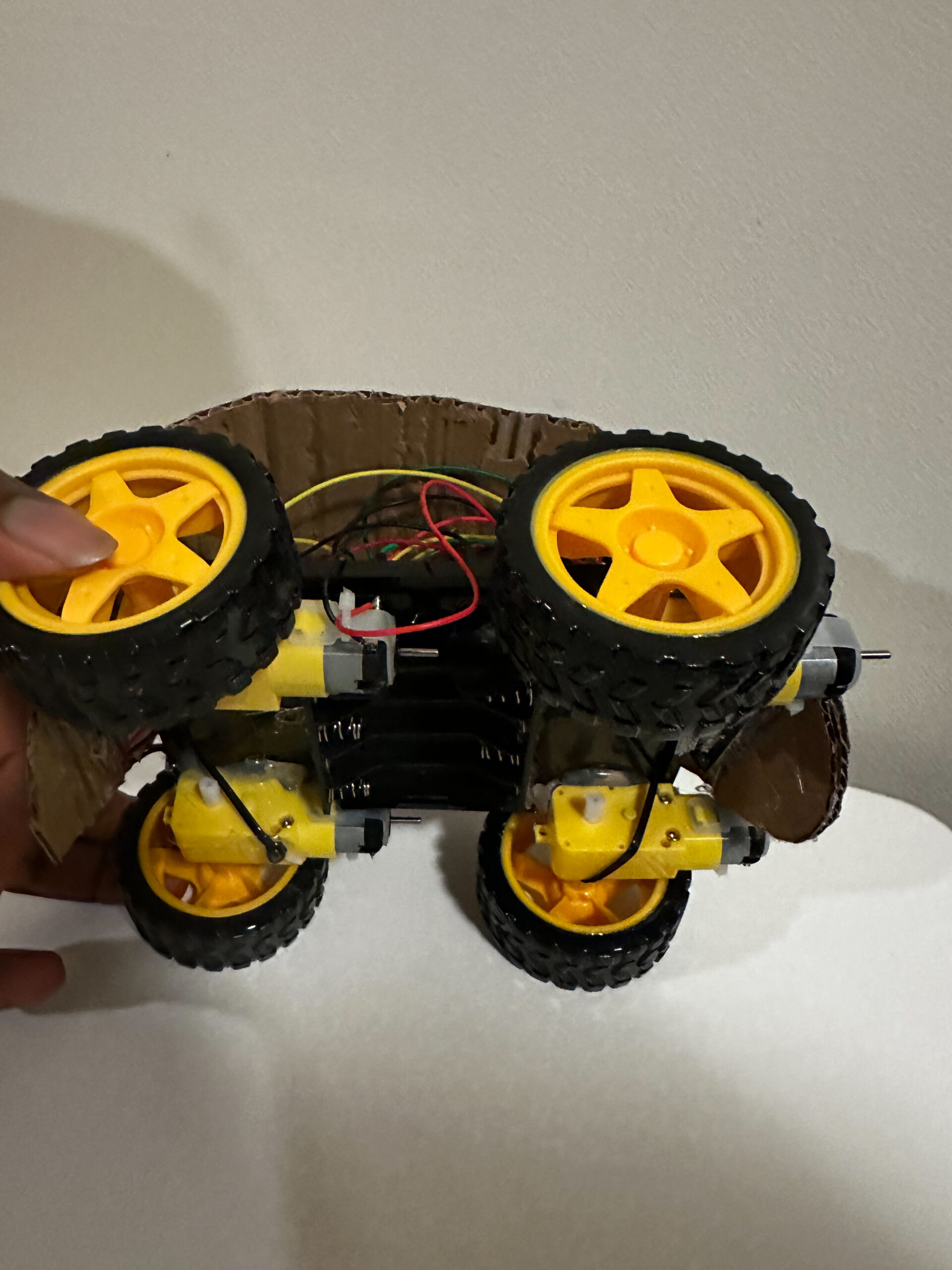

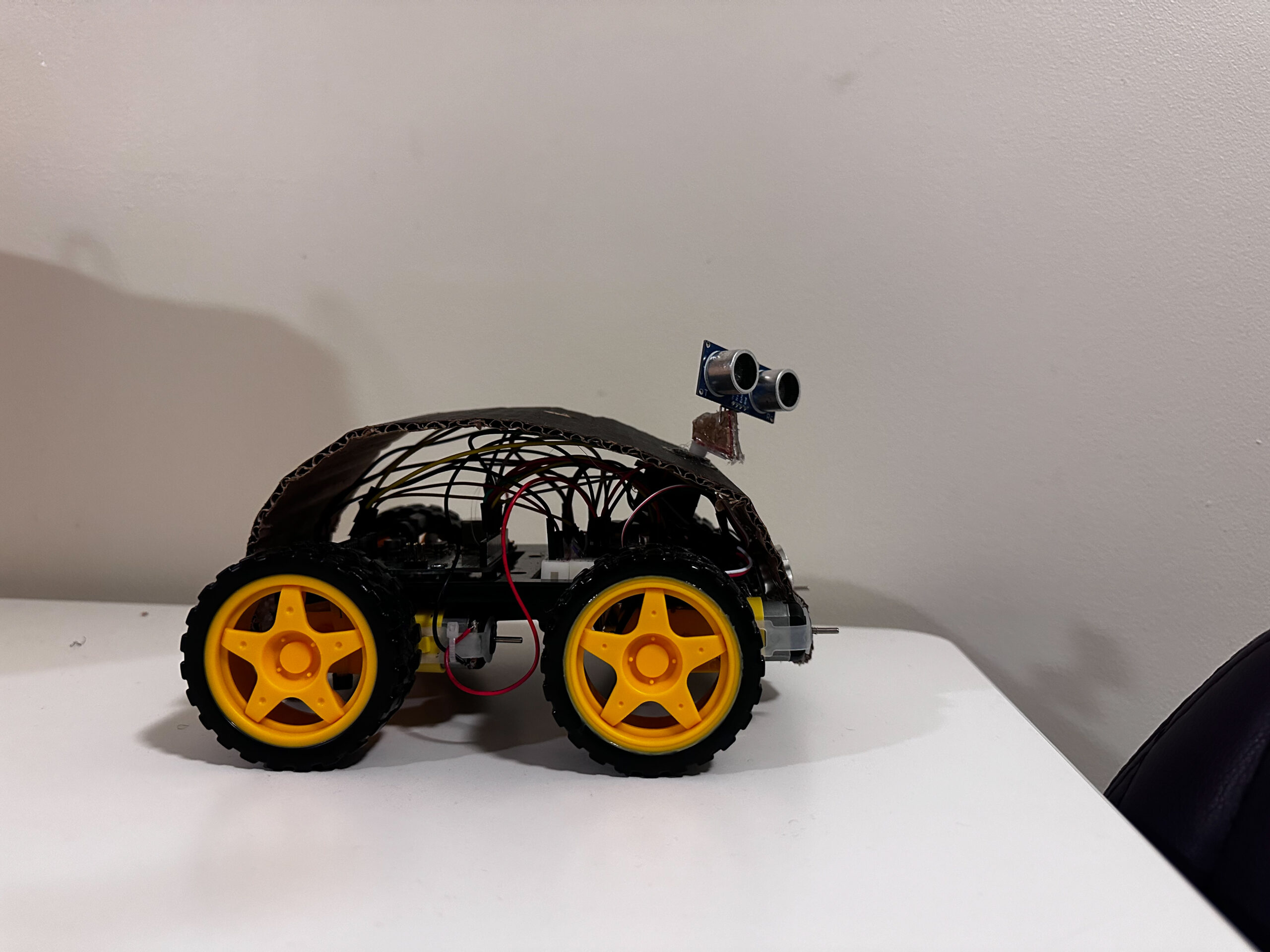

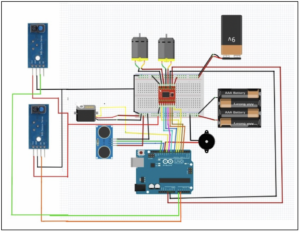

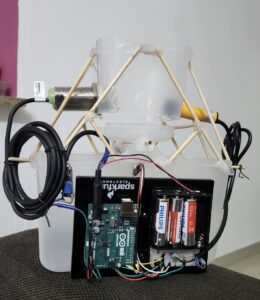

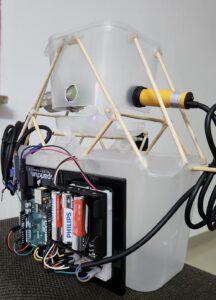

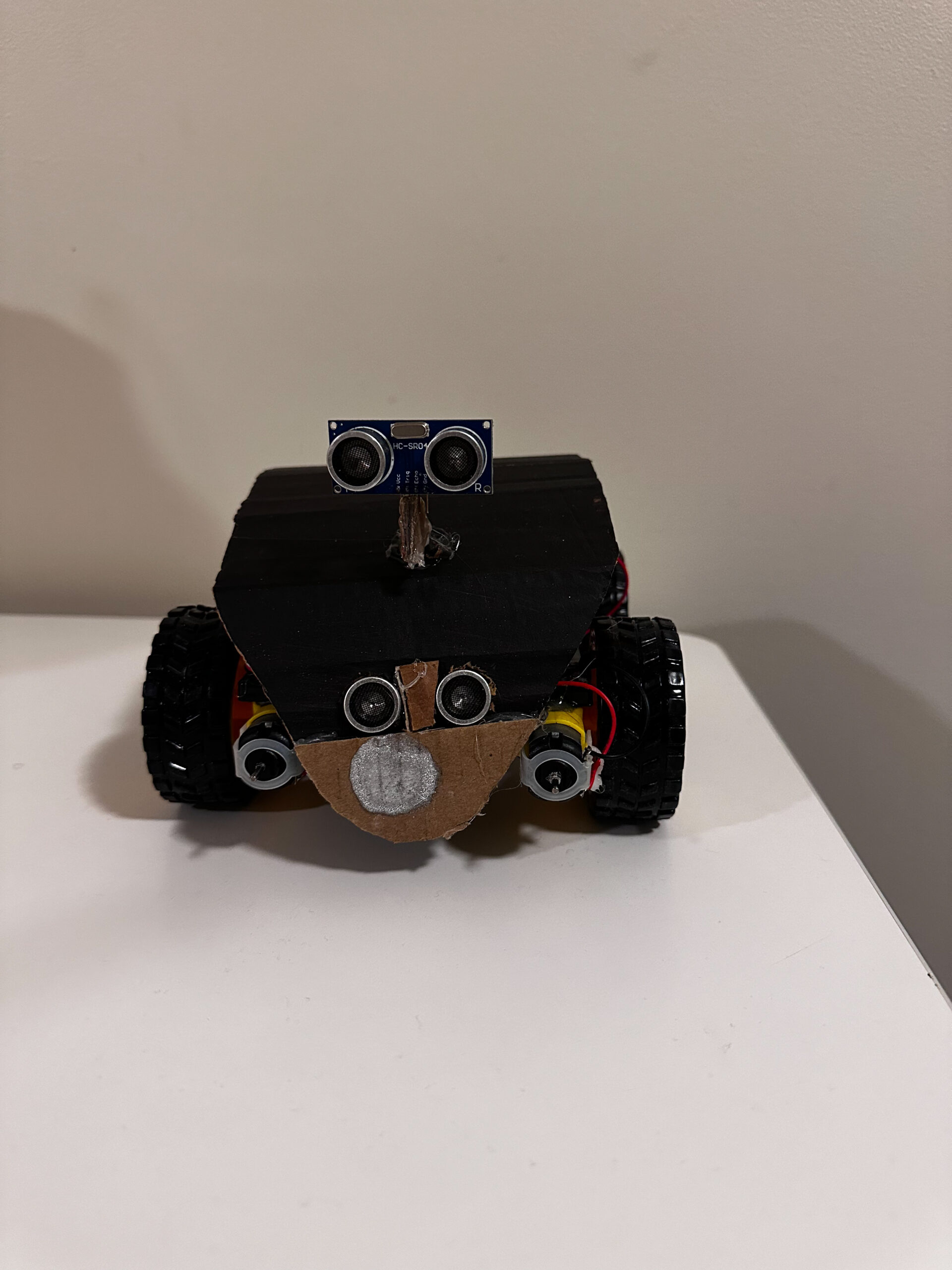

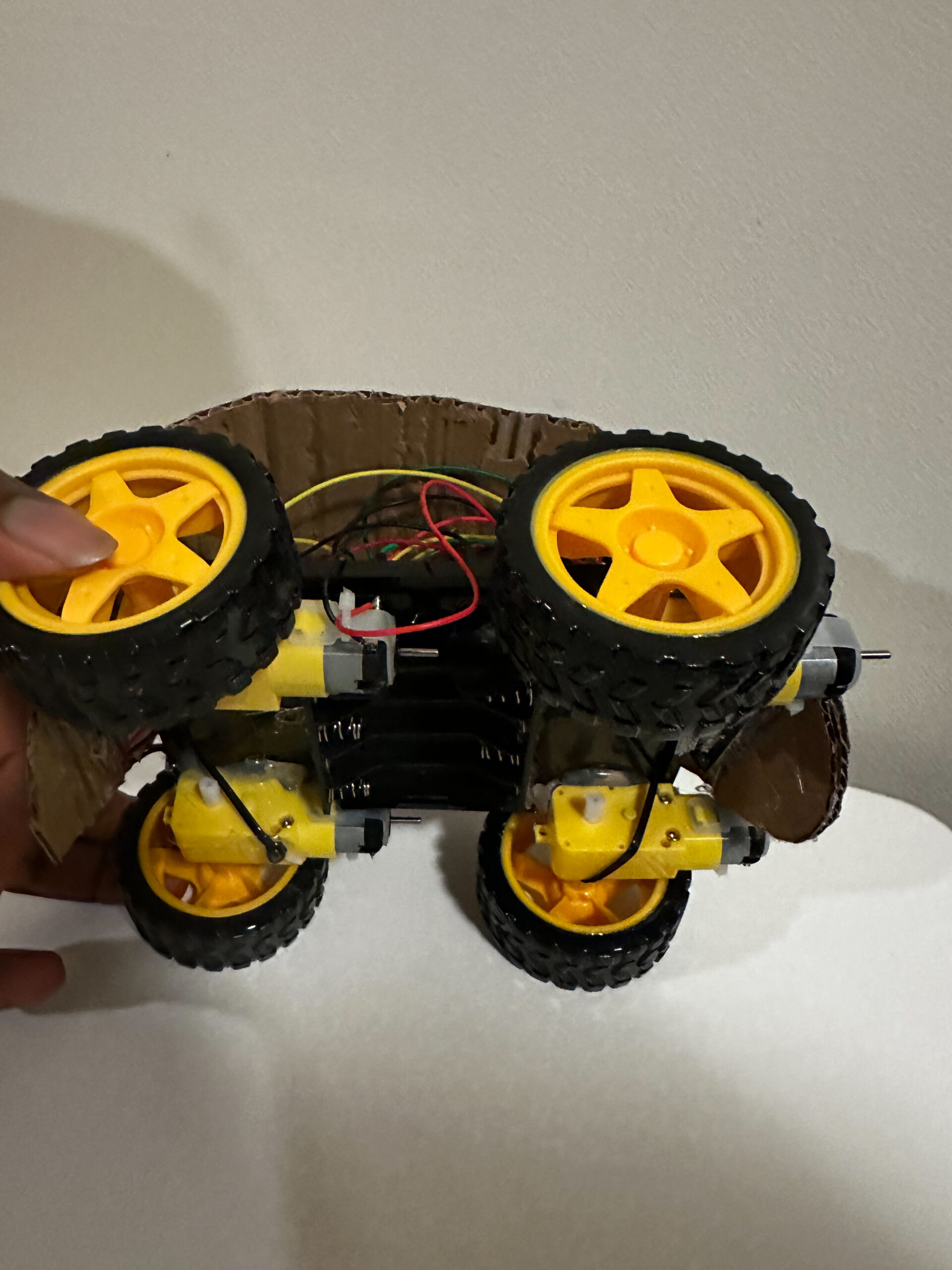

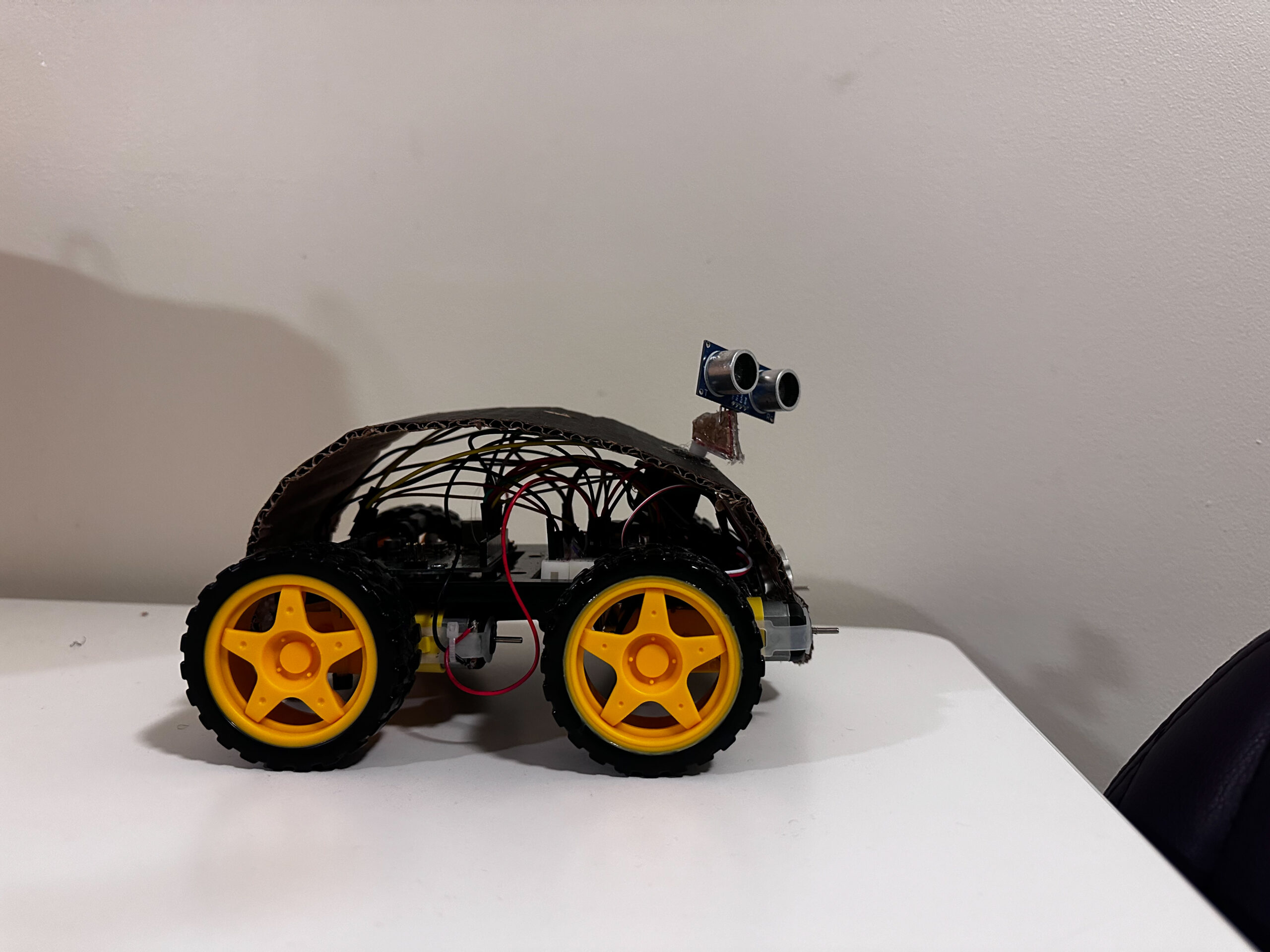

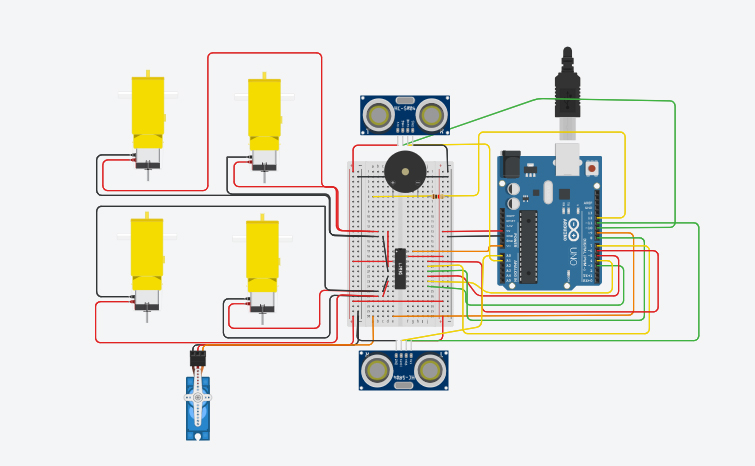

The idea was to create a bot that can be controlled with hand movement using machine learning with the P5.ml library. The P5 sketch has an in-car design with the steering wheel and the Arduino comprises 4dc motors, two ultrasonic sensors, and some LEDs.

Interactive Design:

For user interactivity, I decided to use the P5.js. The computer video webcam helps the machine learning library to detect the movement of the user’s hand and map these movements to the size of the canvas. This information is used to control the steering wheel, which controls the Arduino.

Arduino Code:

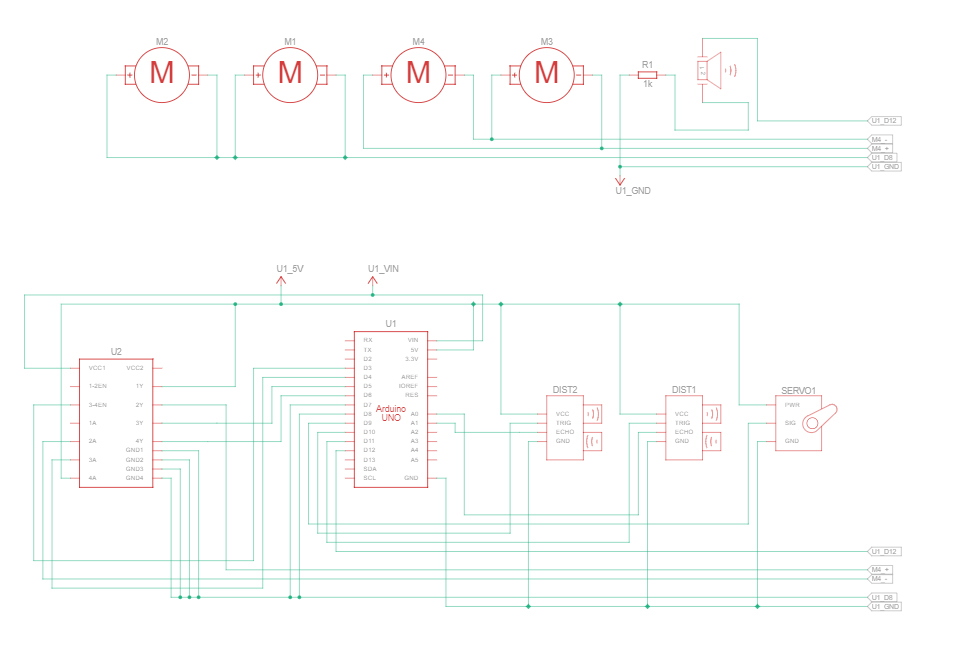

For the Arduino aspect, the motors are controlled using switch cases. The Arduino receives cases from the P5 sketch and based on those cases, the Arduino knows how to control the 4 DC motors. The Arduino uses the ultrasonic sensors to detect obstacles and sends this information to the P5 sketch to be viewed by the user.

#include <Servo.h>//include the Servo library/

#include <time.h>//include the time library for seeding random number

Servo myservo;//creating servo object

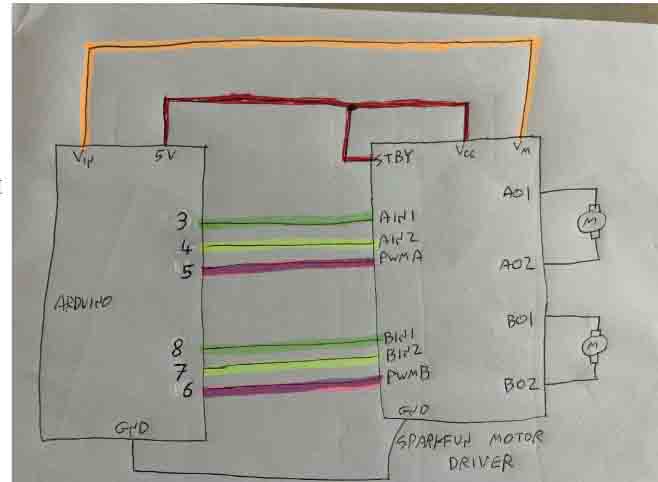

const int ain1Pin = 3;//setting pins for motor for left side which is connected in parallel

const int ain2Pin = 4;

const int pwmAPin = 5;

const int bin1Pin = 8;//setting pinf for motor for right side

const int bin2Pin = 7;

const int pwmBPin = 6;

const int trigPin1 = 11;//setting pins for front ultrasonic sensor

const int echoPin1= A0;//I used A0 pin cause I didnt have space...Please pardon me

const int trigPin2 = 10;//setting pins for back ultrasonic sensor

const int echoPin2 = A1;//here too

const int warningbuzzer=12;//setting the buzzer to 12

//servo motor

const int headmovePin=9;//setting the servo motor pin to 9

int wallstop=0;//initializing the obstacle detection

unsigned long previousMillis = 0;//setting millis to 0

const long interval = 5000;//setting interval for the millis

void setup() {

myservo.attach(headmovePin);//pass the servo pin to the servo library

randomSeed(time(NULL));//seed random number using the current time

pinMode(ain1Pin, OUTPUT);//setting the pins as output and input

pinMode(2, OUTPUT);//light checker

pinMode(ain2Pin, OUTPUT);//motor pin

pinMode(pwmAPin, OUTPUT); // not needed really

pinMode(bin1Pin, OUTPUT);

pinMode(bin2Pin, OUTPUT);

pinMode(pwmBPin, OUTPUT); // not needed really

// Start serial communication so we can send data

// over the USB connection to our p5js sketch

pinMode(trigPin1, OUTPUT);

pinMode(echoPin1, INPUT);

pinMode(trigPin2, OUTPUT);

pinMode(echoPin2, INPUT);

pinMode(warningbuzzer, OUTPUT);

Serial.begin(9600);//setting the serial band

while (!Serial.available()) {

digitalWrite(LED_BUILTIN, HIGH); // on/blink while waiting for serial data

Serial.println("0,0"); // send a starting message

delay(300); // wait 1/3 second

digitalWrite(LED_BUILTIN, LOW);

delay(1000);//delay for a second

}

}

void loop() {

wallstop=crushstop();

//When the serial is detected do this

while (Serial.available()) {//while the serial connection exists

digitalWrite(LED_BUILTIN, HIGH); // led on while receiving data

wallstop=crushstop();//update the wallstop from the crush function

unsigned long currentMillis = millis();//set current millis

if (currentMillis - previousMillis >= interval) {

// save the last time you blinked the LED

previousMillis = currentMillis;

movehead();//if the interval is reached, move the head

}

int movement = Serial.parseInt();//get the movement case from p5

if (Serial.read() == '\n') {//when we read a new line,

switch(movement){//execute the following commmands based on the case

case 0://no movement

analogWrite(pwmAPin, 0);

digitalWrite(ain1Pin, HIGH);

digitalWrite(ain2Pin, LOW);

analogWrite(pwmBPin, 0);

digitalWrite(bin1Pin, LOW);

digitalWrite(bin2Pin, HIGH);

break;

case 1://forward

analogWrite(pwmAPin, 255);

digitalWrite(ain1Pin, LOW);

digitalWrite(ain2Pin, HIGH);

analogWrite(pwmBPin, 255);

digitalWrite(bin1Pin, HIGH);

digitalWrite(bin2Pin, LOW);

break;

case 2://reverse

analogWrite(pwmAPin, 255);

digitalWrite(ain1Pin, HIGH);

digitalWrite(ain2Pin, LOW);

analogWrite(pwmBPin, 255);

digitalWrite(bin1Pin, LOW);

digitalWrite(bin2Pin, HIGH);

break;

case 3://right front

analogWrite(pwmBPin, 255);

digitalWrite(bin1Pin, HIGH);

digitalWrite(bin2Pin, LOW);

break;

case 4://left front

analogWrite(pwmAPin, 255);

digitalWrite(ain1Pin, LOW);

digitalWrite(ain2Pin, HIGH);

break;

case 5://right back

analogWrite(pwmBPin, 255);

digitalWrite(bin1Pin, LOW);

digitalWrite(bin2Pin, HIGH);

break;

case 6://left back

analogWrite(pwmAPin, 255);

digitalWrite(ain1Pin, HIGH);

digitalWrite(ain2Pin, LOW);

break;

default://if not case is gotten within our expected range, stop

analogWrite(pwmAPin, 0);

digitalWrite(ain1Pin, HIGH);

digitalWrite(ain2Pin, LOW);

analogWrite(pwmBPin, 0);

digitalWrite(bin1Pin, LOW);

digitalWrite(bin2Pin, HIGH);

break;

}

delay(5);

Serial.println(wallstop);//send the detection to p5

}

}

}

int crushstop(){//this function returns 1 when an obstacle is ahead and 2 when an obstacle is behind

int wallstop=0;//initialize wallstop

digitalWrite(trigPin1, LOW);

delayMicroseconds(2); //basically shooting beems and using the time it takes to bounce back to calculate distance

digitalWrite(trigPin1, HIGH);

delayMicroseconds(10);

digitalWrite(trigPin1, LOW);

// Time it takes for the pulse to travel back from the object long

int duration1 = pulseIn(echoPin1, HIGH);

// Universal conversion of time into distance in cm

int distance1 = duration1 * 0.034 / 2;//divided by two beause its a two way thing

digitalWrite(trigPin2, LOW);

delayMicroseconds(2);

digitalWrite(trigPin2, HIGH);

delayMicroseconds(10);

digitalWrite(trigPin2, LOW);

// Time it takes for the pulse to travel back from the object long

int duration2 = pulseIn(echoPin2, HIGH);

// Universal conversion of time into distance in cm

int distance2 = duration2 * 0.034 / 2;

if(distance1<5){//if collision is detected behind, send 2

wallstop=2;

tone(warningbuzzer,2000);//play the tone

delay(5);

}

else if(distance2<5){

wallstop=1;//if collision is detected infront, send 1

tone(warningbuzzer,2000);//play the tone

delay(5);

}

else{

wallstop=0;

noTone(warningbuzzer);//if nothing is detected dont play a tone

}

return wallstop;//return this info

}

void movehead(){

myservo.write(random(0, 180));//move the head to a random number between 0 and 180

delay(15);

}

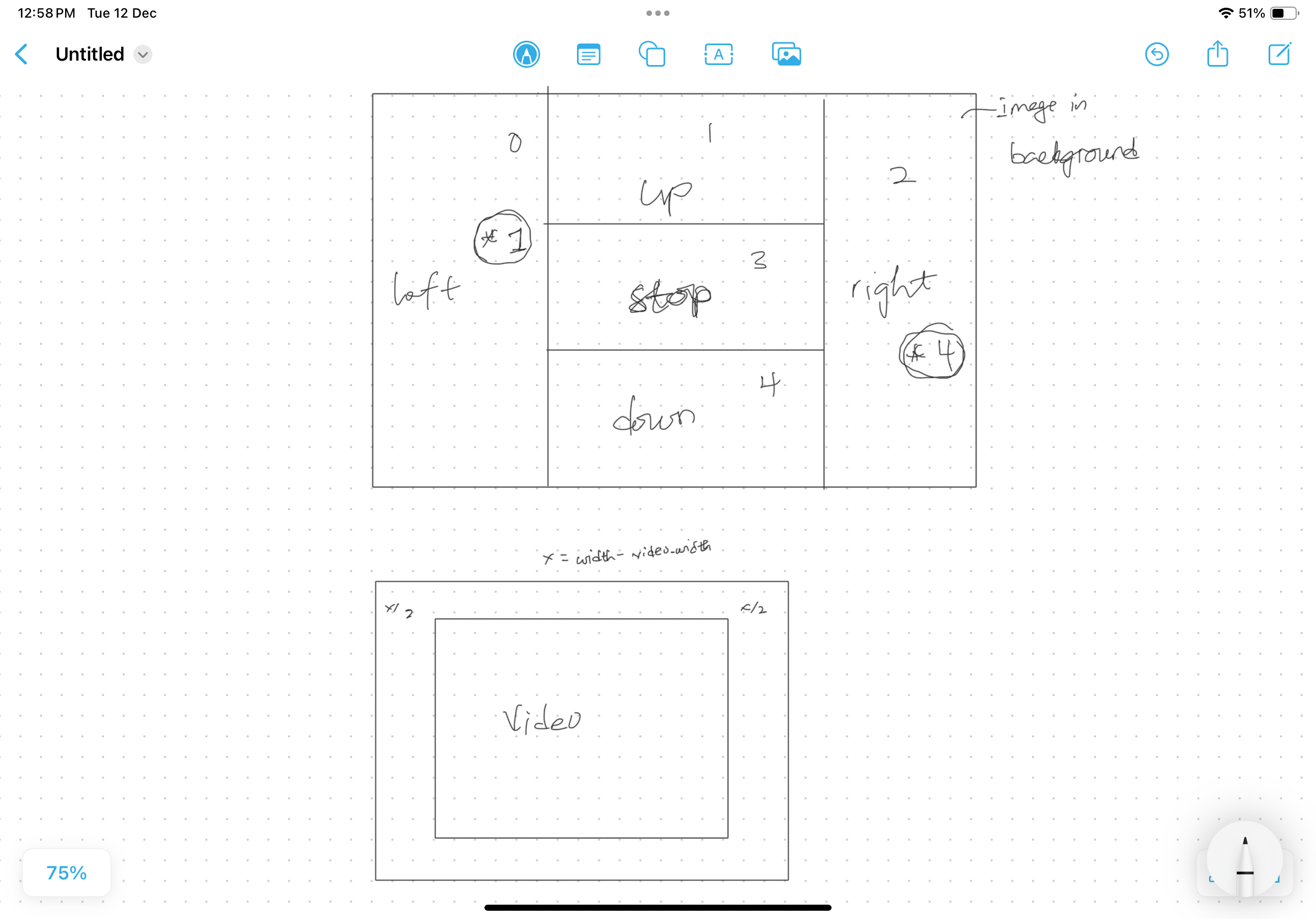

P5.js:

For this part, the P5.js sketch receives the user hand positions info from the P5.ml library and maps it to get its corresponding points on the canvas. After, these values are averaged and the average-X value is used to control the steer’s left or right turn. The average-Y value is used to control the forward and backward movement. Based on this cases are developed and sent to the Arduino for execution of tasks.

The P5 sketch is divided into five parts

Serial connection:

This part is responsible for connecting the Arduino to the P5 sketch and since its not my code I will not post it

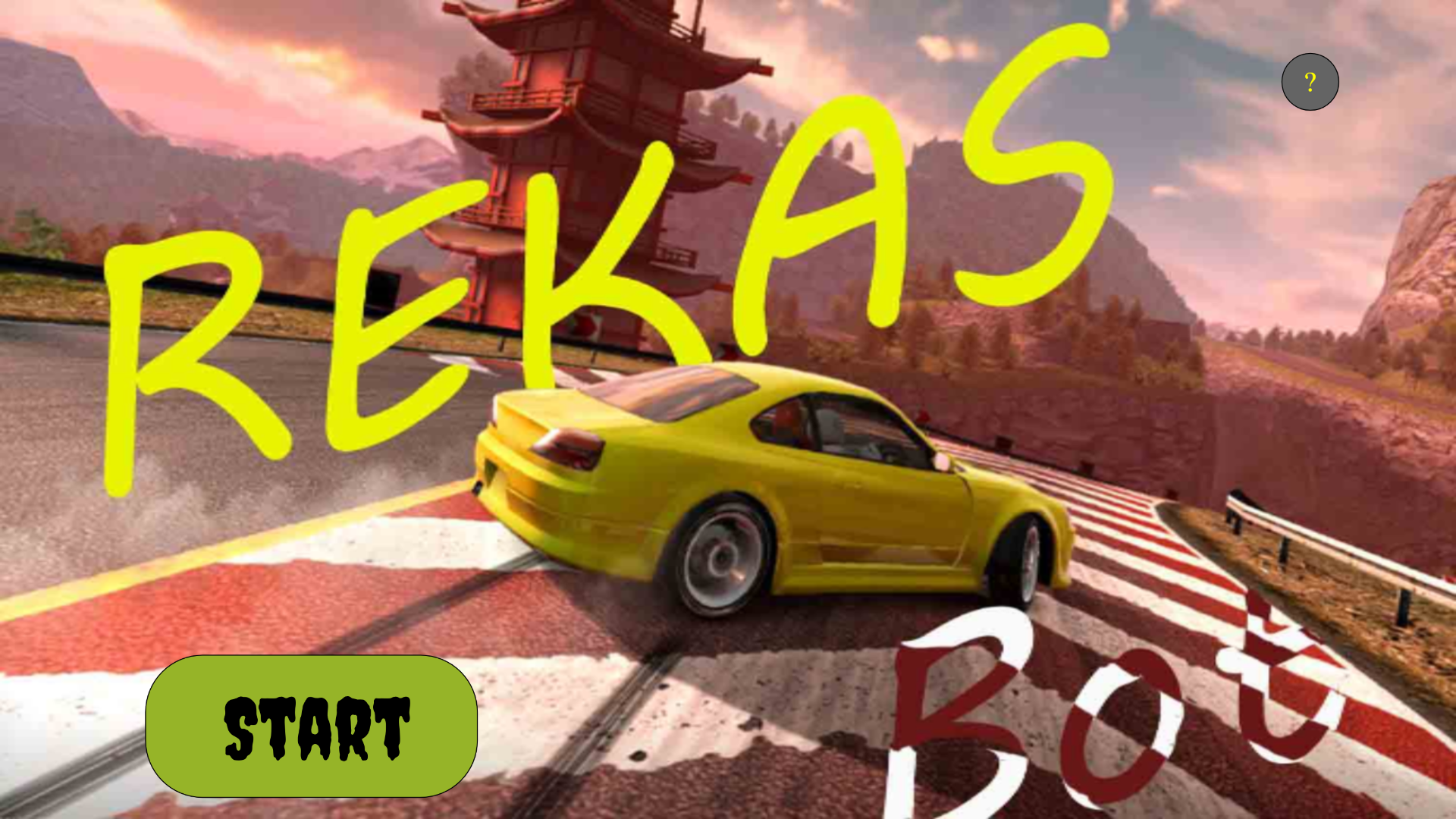

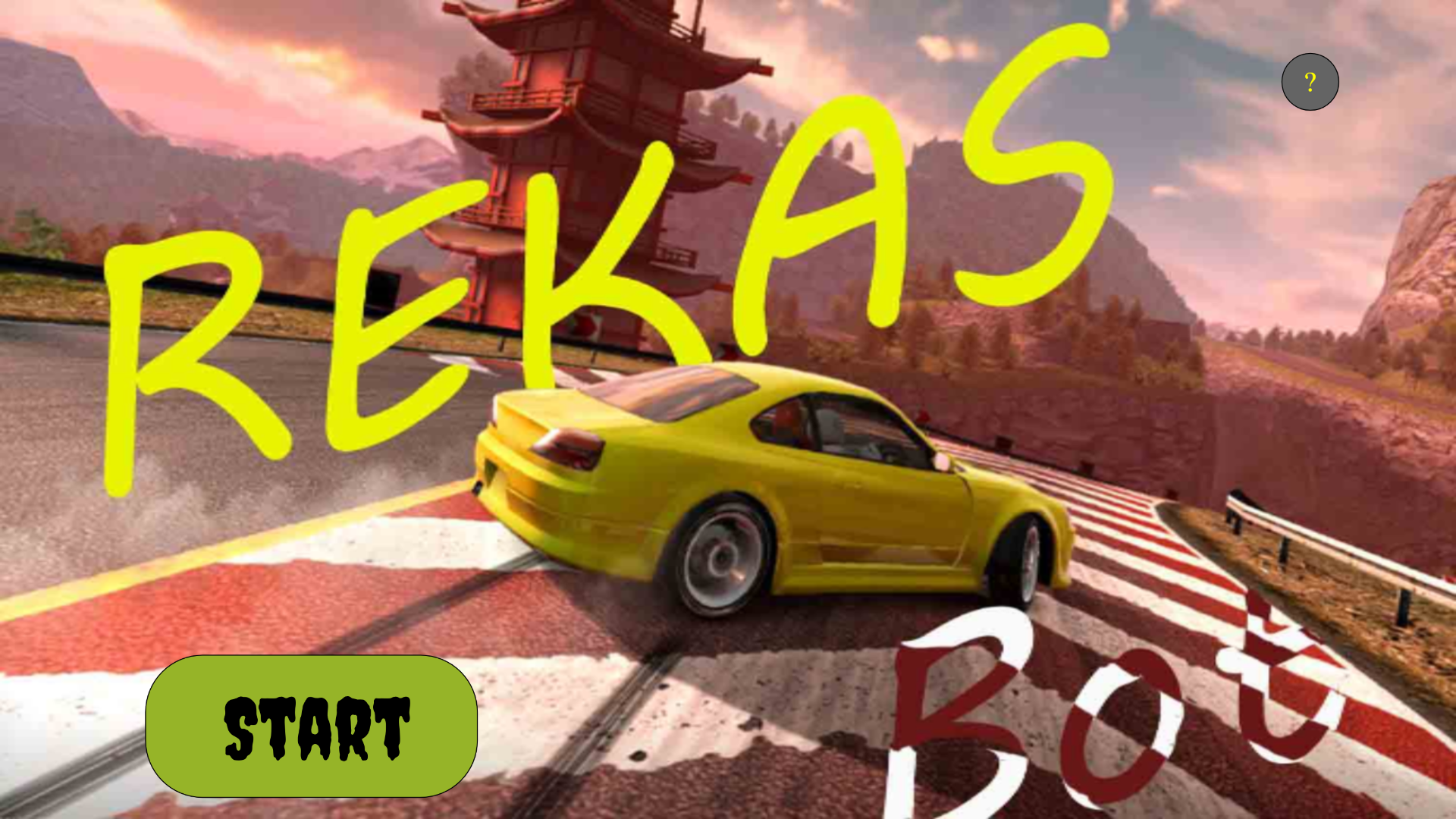

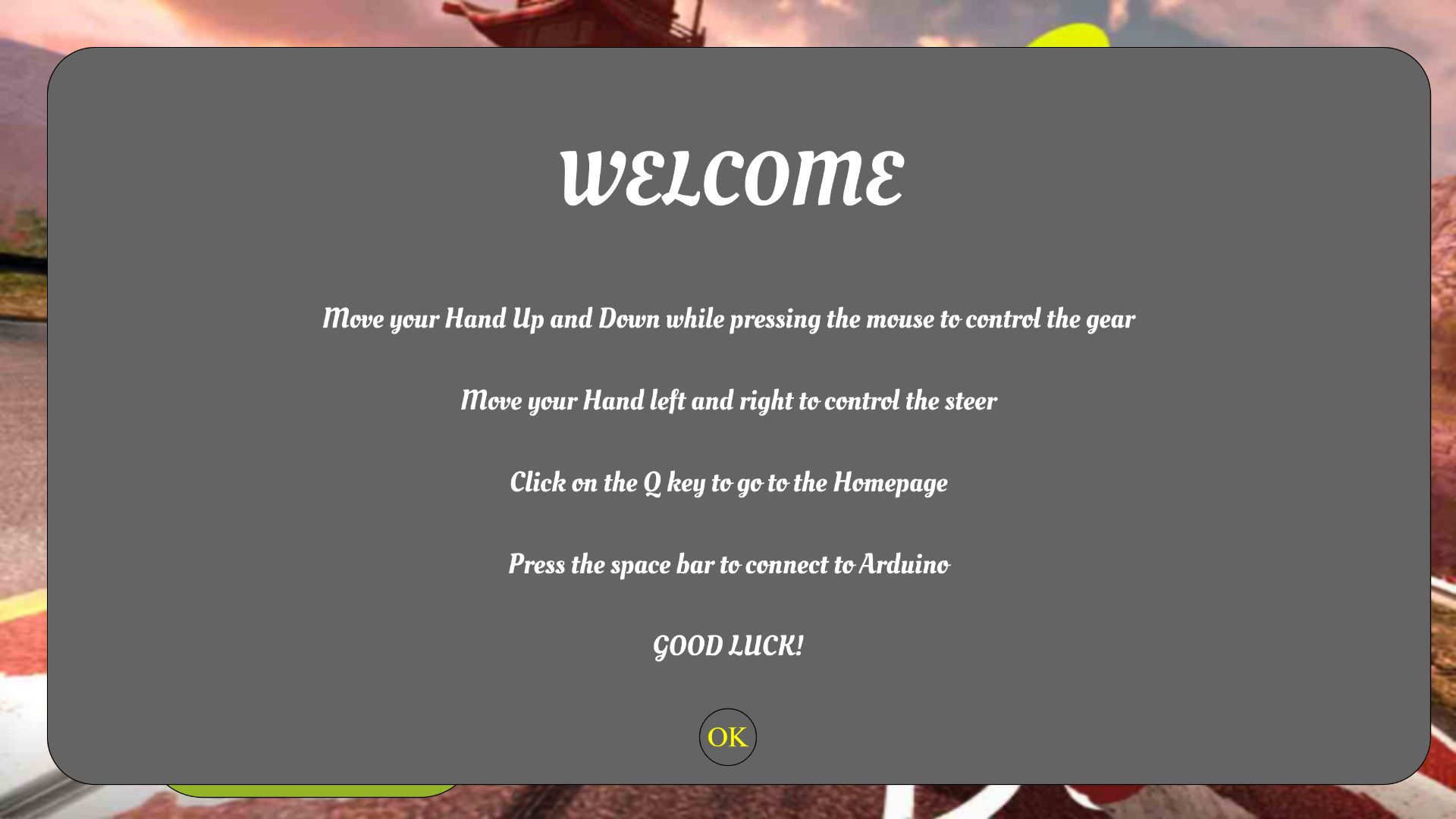

Intro Page:

The next part is the intro page. Is welcomes the user into the project and also gives some info to the user about how to use the vehicle. I made the background picture myself using photoshop and then I added some buttons and sounds

class ipage{

constructor(IB,S1,S2,F1,F2){//receive all needed variables as in images and sound

this.BG=IB;//the background

this.S1=S1;//sound

this.playbool=false;//boolean to start game

this.helpbool=false;//boolean to open help page

this.F2=F2//font

}

show(){//this shows the designs in the page

this.BG.resize(windowWidth,windowHeight);//resize the introimage

image(this.BG,0,0);//displaying background

textAlign(CENTER);

this.createhelp();//calling the help function for the help page

this.playbox();//calling the playbox button function

if(this.helpbool){//if the helpbool is true display the help page

this.helppage();

}

return this.playbool;//this returns true if the play button is pressed

}

playbox(){//this function displays the start button

rectMode(CORNER);

fill(150,180,40);

if(mouseX>windowWidth*0.1&&mouseX<(windowWidth*0.1)+350&&mouseY>windowHeight*0.8&&mouseY<(windowHeight*0.8)+150){

fill(150,0,0);//creating the hover effect

}

if(mouseX>windowWidth*0.1&&mouseX<(windowWidth*0.1)+350&&mouseY>windowHeight*0.8&&mouseY<(windowHeight*0.8)+150&&mouseIsPressed&&!this.helpbool){

S2.pause();// the play is pressed, play pause the background music

this.S1.play();//playing the start button pressed sound

this.playbool=true;//sets the playboolean to true

}

rect(windowWidth*0.1,windowHeight*0.8,350,150,60);//drawing the start button

fill(0);

textFont(F1);

textSize(90);

textAlign(CENTER);

text("Start",windowWidth*0.1+180,windowHeight*0.8+110);

}

createhelp(){

fill(100);

if(dist(mouseX,mouseY,windowWidth*0.9,windowHeight*0.1)<=30){

fill(60);//create hover effect

}

if(dist(mouseX,mouseY,windowWidth*0.9,windowHeight*0.1)<=30&&mouseIsPressed){

this.helpbool=true;//set boolean to open help page

}

circle(windowWidth*0.9,windowHeight*0.1,60);//these following code just creates the help button

fill(255,255,0);

textSize(30);

textFont(NORMAL);

text("?",windowWidth*0.9,windowHeight*0.1+10);

}

helppage(){

fill(100);

rect(50,50,windowWidth*0.95,windowHeight*0.9,50);

textFont(this.F2);

fill(255);

textSize(80);

text('WELCOME',windowWidth*0.5,windowHeight*0.25);

textSize(30);

text('Move your Hand Up and Down while pressing the mouse to control the gear',windowWidth*0.5,windowHeight*0.4);

text('Move your Hand left and right to control the steer',windowWidth*0.5,windowHeight*0.5);

text('Click on the Q key to go to the Homepage',windowWidth*0.5,windowHeight*0.6);

text('Press the space bar to connect to Arduino',windowWidth*0.5,windowHeight*0.7);

text('GOOD LUCK!',windowWidth*0.5,windowHeight*0.8);

fill(100);

if(dist(mouseX,mouseY,windowWidth*0.5,windowHeight*0.9)<=30){

fill(60);//create hover effect

}

if(dist(mouseX,mouseY,windowWidth*0.5,windowHeight*0.9)<=30&&mouseIsPressed){

this.helpbool=false;//set boolean to close help page

}

circle(windowWidth*0.5,windowHeight*0.9,60);//these following code just creates the ok button

fill(255,255,0);

textSize(30);

textFont(NORMAL);

text("OK",windowWidth*0.5,windowHeight*0.9+10);

}

}

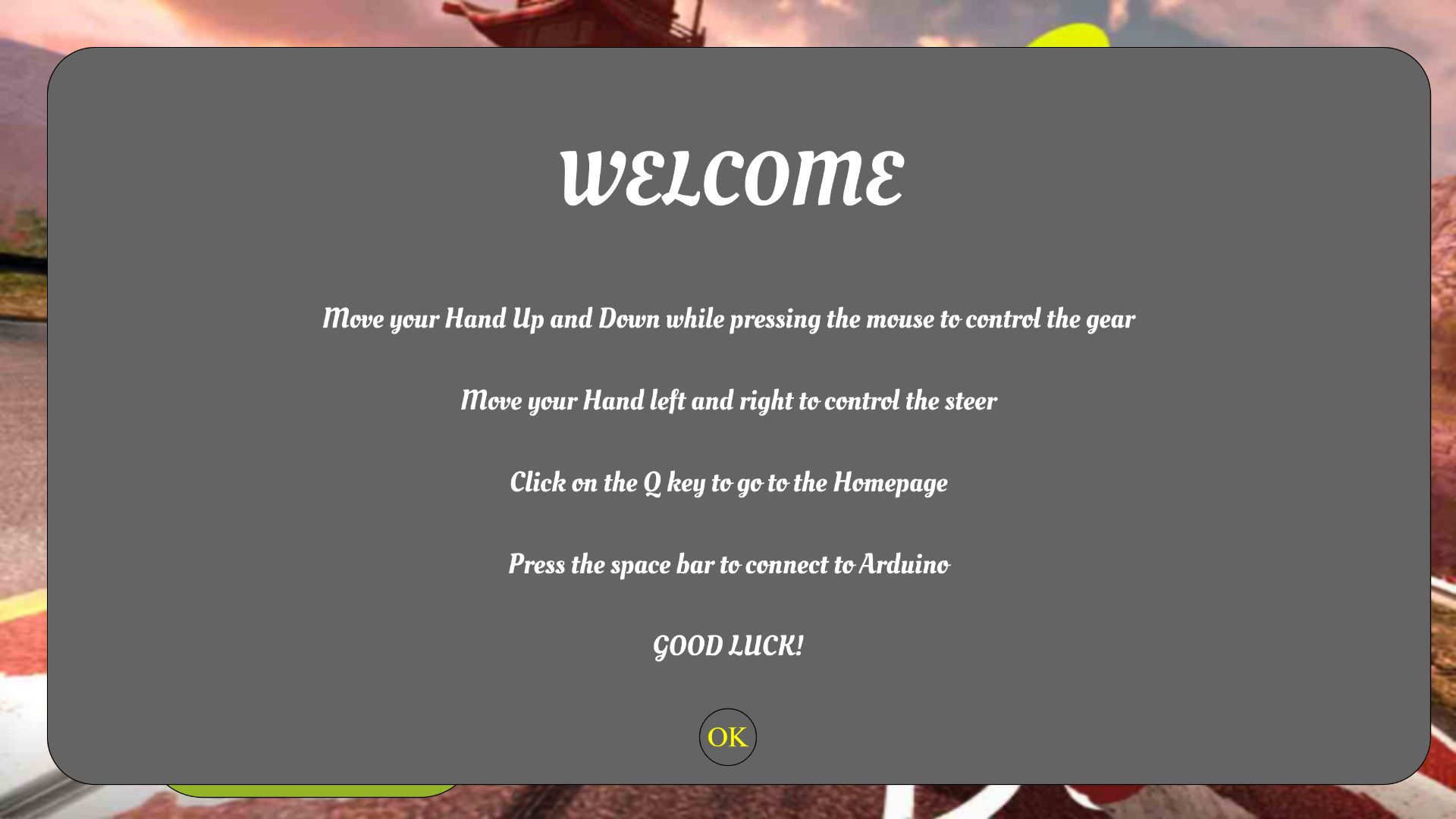

Help Page:

This page is just to give the user info about the game and wish them luck as they embark on the Journey.

the code is found in the intro class and the page is controlled with the use of Boolean variables.

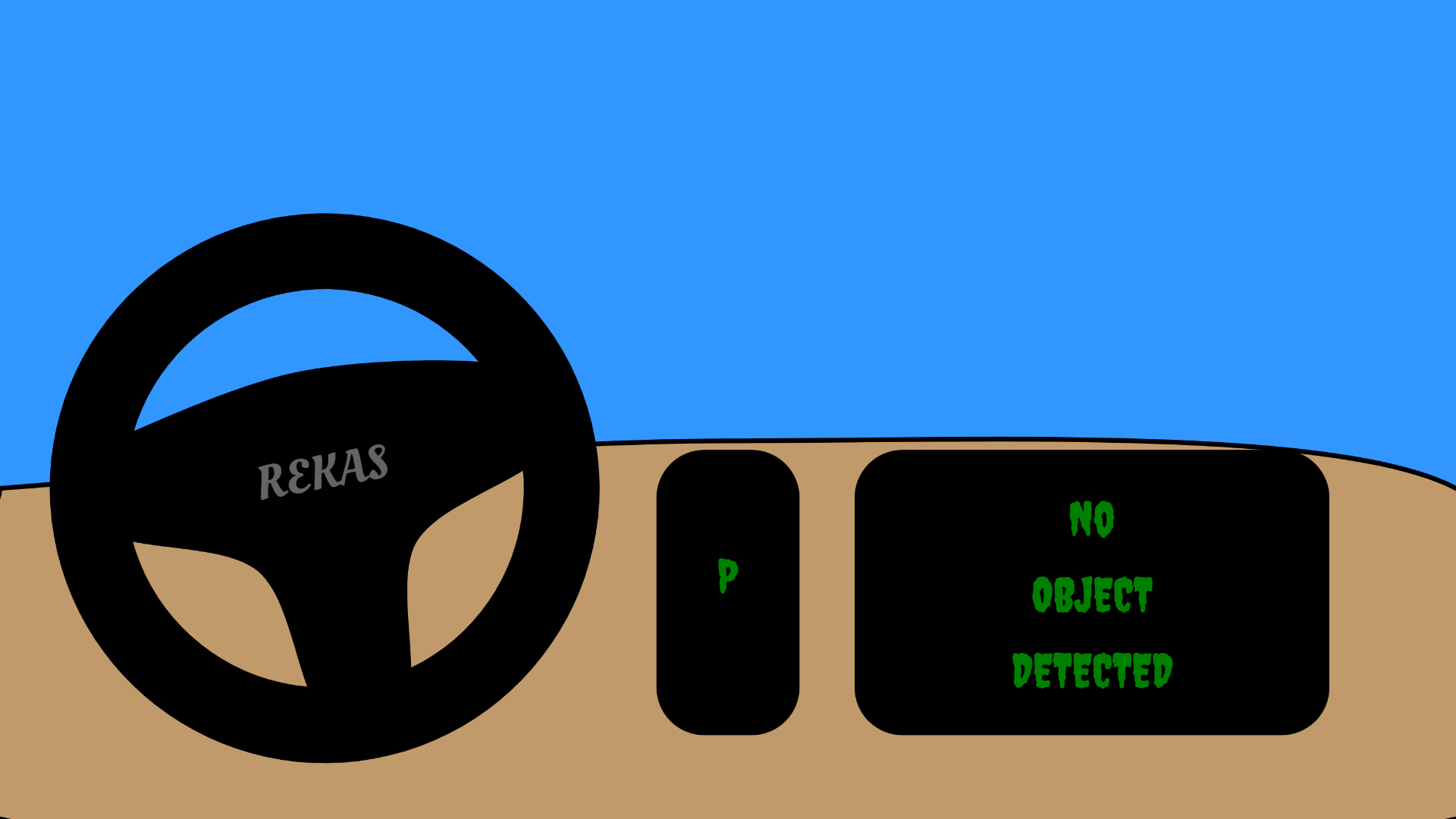

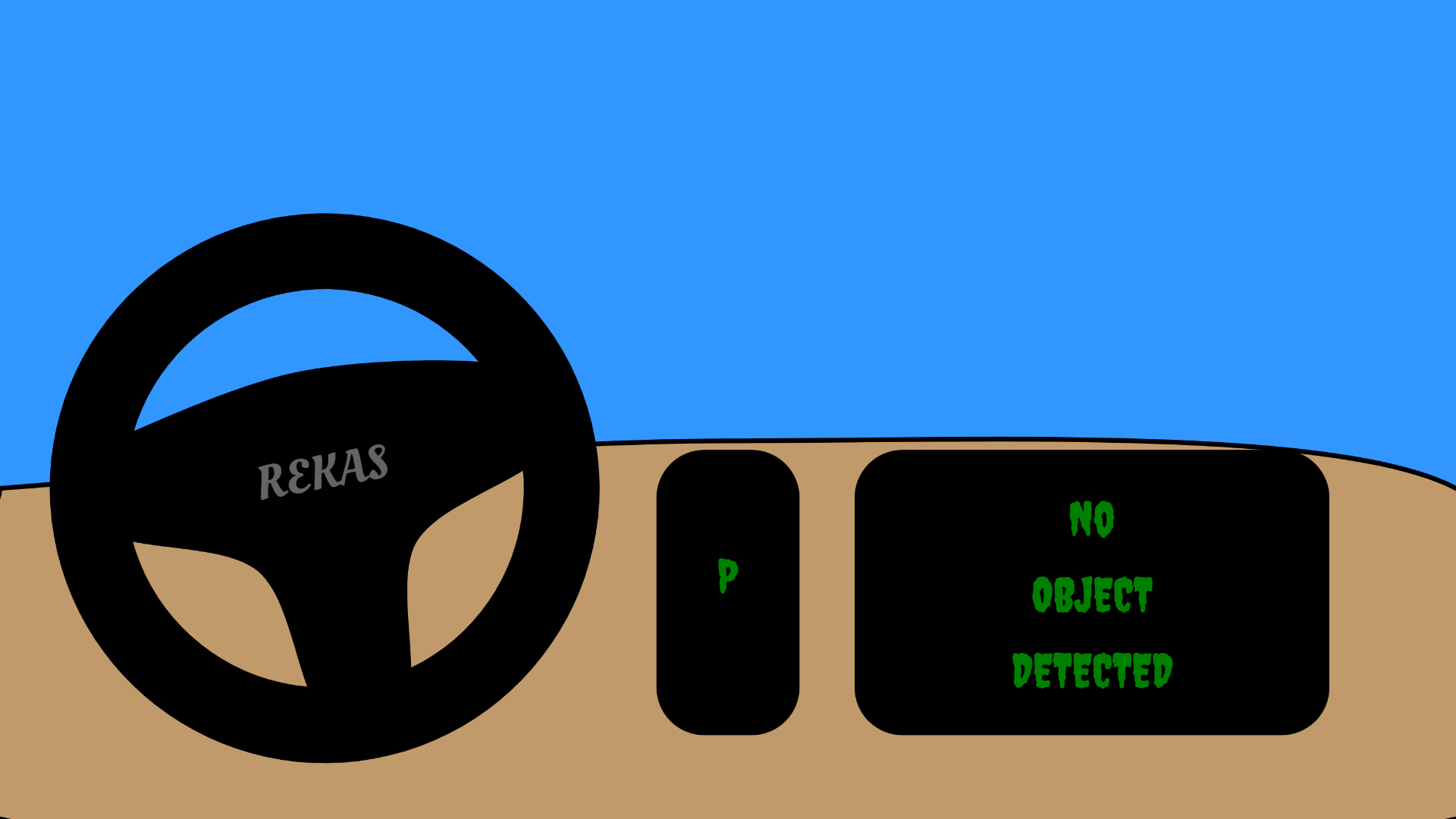

Dashboard:

Coming into the main page, the Dashboard shows the gearbox and the collision screen that alerts the user when the user is close to an obstacle.

class dash{//this class prints the dashboard, the gear and the detection screen

constructor(dashY){

this.Y=dashY;//the Y coordinate to which the dashboard is drawn

this.movementFB=0;//the front and back movement counter

this.gearY=0;//this controls the gearmovement

}

showdash(){

push();//creating the dashboard

strokeWeight(5)//set stroke weight to 5

fill(193, 154, 107);//fill with brown

beginShape();//we draw the dashboard

curveVertex(0,this.Y);

curveVertex(0,this.Y);

curveVertex(windowWidth/2,this.Y-50);//creating the curve look

curveVertex(windowWidth,this.Y);

curveVertex(windowWidth,windowHeight);

curveVertex(0,windowHeight);

curveVertex(0,this.Y);

curveVertex(0,this.Y);

endShape();

pop();

}

showgear(gearY){//this function shows the gear

this.gearY=gearY;//capies value of the gearY from handpose

rectMode(CENTER);//set rectange mode

textSize(50);

fill(0);//fill with black

rect(windowWidth*0.5,this.Y+110,150,300,50);

if(mouseIsPressed){//if the mouse is pressed means gear is being controlled

if(this.gearY<windowHeight*0.35){

this.movementFB=1;//set gear to drive

}

else if(this.gearY>windowHeight*0.5){

this.movementFB=2;//set gear to reverse

}

else{

this.movementFB=0;//set gear to P

}

}

textAlign(CENTER);//align text to center

textSize(50);

fill(0,128,0);//fill with green

switch(this.movementFB){

case 0:

text('P',windowWidth*0.5,this.Y+110);//p for parking

break;

case 1:

text('D',windowWidth*0.5,this.Y+110);//D for drive

break;

case 2:

text('R',windowWidth*0.5,this.Y+110);//R for reverse

break;

}

textAlign(LEFT);

textSize(12);

return this.movementFB;//return the gear movement info

}

showScreen(wallstop){//this shows the detection

rectMode(CENTER);

textSize(50);

textAlign(CENTER);

fill(0);

rect(windowWidth*0.75,this.Y+110,500,300,50);//create screen

fill(128,0,0);//fill the text with red

if(wallstop==1){//if the front ultrasonic sensor is the one sensing

text('OBJECT',windowWidth*0.75,this.Y+50);

text('DETECTED',windowWidth*0.75,this.Y+130);

text('AHEAD',windowWidth*0.75,this.Y+210);

}

else if(wallstop==2){//if the back ultrasonic is the one sensing

text('OBJECT',windowWidth*0.75,this.Y+50);

text('DETECTED',windowWidth*0.75,this.Y+130);

text('BEHIND',windowWidth*0.75,this.Y+210);

}

else{

fill(0,128,0);//fill the text with green

text('No',windowWidth*0.75,this.Y+50);

text('OBJECT',windowWidth*0.75,this.Y+130);

text('DETECTED',windowWidth*0.75,this.Y+210);

}

textAlign(LEFT);

textSize(12);

}

}

In order to show the gear box info it gets info from the poseNet calculations done in the sketch and for the collision screen it uses info from the ultrasonic sensors.

The Steering wheel:

Though also part of the Dashboard, this is a separate class because it controls the left and right movement using info from the other parts. That is, is uses info from the gear box and collision screen. It is not a picture downloaded from somewhere but a hand coded diagram.

class Steer{//this class creates the steer and controls the car movement front and back

constructor(ctr,F2,X=windowWidth/3,Y=windowHeight/2){//takes the steerX,the font and the position for the steer to be placed

this.angle=0;//equate the angle to 0

this.X=X;//set the X and Y for the placement of the steering wheel

this.Y=Y;

this.ctr=ctr;

this.movementLR=0;//create this Left right variable to store the movement

this.F2=F2;

}

show(ctr){//takes steer x

this.ctr=ctr;//update the ctr with steerX

push();//designing the steering using stack so that it can be rotated entirely at once

translate(this.X,this.Y);//making the orijin these

rotate(this.angle);//causes the rotation

noFill(0);

strokeWeight(80);

rectMode(CENTER);

circle(0,0,500);

fill(0);

stroke(0);

strokeWeight(12);

beginShape();

curveVertex(-230,-80);

curveVertex(-230,-80);

curveVertex(0,-120);

curveVertex(230,-80);

curveVertex(230,0);

curveVertex(80,70);

curveVertex(40,230);

curveVertex(-40,230);

curveVertex(-80,70);

curveVertex(-230,0);

curveVertex(-230,-80);

curveVertex(-230,-80);

fill(0);

endShape();

fill(100);

noStroke()

textSize(50)

textAlign(CENTER);

textFont(this.F2);

text('REKAS',0,0);//steering wheel/car brand

pop();

if(this.ctr>0&&this.ctr<windowWidth){//while the value is within our range

this.angle=map(this.ctr,0,windowWidth,-PI/2,PI/2);//update angle based on this

}

}

steerTurn(movementFB,wallstop){//this function controls the turning of the steer

if(this.angle<-PI/7.5&&movementFB==1&&wallstop!=1){

this.movementLR=4;//front left

}

else if(this.angle<-PI/7.5&&movementFB==2&&wallstop!=2){

this.movementLR=6;//back left

}

else if(this.angle>=-PI/7.5&&this.angle<-PI/8){

this.movementLR=0;//to prevent bugs

}

else if(this.angle>=-PI/7&&this.angle<PI/8&&movementFB==1&&wallstop!=1){

this.movementLR=1;//move straight ahead

}

else if(this.angle>=-PI/7&&this.angle<PI/7&&movementFB==2&&wallstop!=2){

this.movementLR=2;//reverse

}

else if(this.angle>=PI/7&&this.angle<PI/5){

this.movementLR=0;//yeah

}

else if(this.angle>=PI/5&&movementFB==1&&wallstop!=1){

this.movementLR=3;//front right

}

else if(this.angle>=PI/5&&movementFB==2&&wallstop!=2){

this.movementLR=5;//back right

}

else{

this.movementLR=0;//dont move

}

return this.movementLR;

}

}

Sketch:

This is the last part that kind of sums everything up. This is where all the other components come together to produce this artwork. This is also where the poseNet functions and full screen Functions are declared.

let mySteer;//variable going to store steer object

let myDash;//gonna store the dashboard object

let handpose;//gonna store posenet object

let video;//gonna store video object

let predictions = [];//gonna store set of predictions from posenet

let steerX=300;//gonna store the average x coordinate of the hand

let gearY=250;//gonna store the average y coordinate of the hand

let movementLR=0;//gonnna store the left and right movement

let movementFB=0;//gonna store the front and back movement

let wallstop=0;//gonna store the obstacle detection

let steercontrol=0;//gonna control steer to make it feel smooth

let IntroBackground;//intropage background

let S1;//sound 1(button)

let S2;//sound 2

let F1;

let F2;

let introp;//gonna store intropage object

let introbool=true;//going to control the intropage display

let gamebool=false;//going to control the mainpage display

function preload(){

//in this preload function we will load all the uploads we need before we even start the game.

IntroBackground=loadImage("intro1.jpg");//this is for the background

S1=loadSound("button.mp3");//these sets are for the sounds

S2=loadSound("msound.mp3");

F1=loadFont("font1.ttf");//these sets are for the fonts

F2=loadFont("font2.ttf");

}

function setup() {

createCanvas(windowWidth, windowHeight);

video = createCapture(VIDEO);//capture video using camera

video.size(width, height);//set the size of the video to that of the screen

steercontrol=windowWidth/2//set the steercontrol for smoothness

handpose = ml5.handpose(video);//get posenet from the video feed using the ml library

// This sets up an event that fills the global variable "predictions"

// with an array every time new hand poses are detected

handpose.on("predict", results => {

predictions = results;

});

// Hide the video element, and just show the canvas

video.hide();

introp=new ipage(IntroBackground,S1,S2,F1,F2);//create intropage object

mySteer=new Steer(steerX,F2,windowWidth*0.5,windowHeight*0.85);//create steer object

myDash=new dash(windowHeight*0.85);//create dashboard object

S2.loop();//start playing the sound but with loop property

}

function draw() {

if(introbool){//if the introbool is true show intropage

gamebool=introp.show();//update gamebool from intro.show function

if(gamebool){introbool=false;}//if the gamebool is true,set intro to false

}

else{

background(50,150,255);

myDash.showdash()//show the dash

drawKeypoints();//call this function for geting info from the video hand detection

movementFB=myDash.showgear(gearY);//update the front back movement from the showgear function

movementLR=mySteer.steerTurn(movementFB,wallstop);//update the leftright movement from the steerturn function

if(steerX>0&&steerX<windowWidth){//if the steerX is within the range we want

mySteer.show(steerX);//show the steer with this value

steercontrol=steerX;//update the steercontrol incase we stop getting data

}

else{//if the steerX is not in our range,

if(steercontrol<windowWidth/2-5){steercontrol+=10;}//using our steercontrol,slowly move the steer to the center

else if(steercontrol>windowWidth/2+5){steercontrol-=10;}

mySteer.show(steercontrol);

}

myDash.showScreen(wallstop);//show the screen with the wallstop getten form the Arduino

}

}

function keyPressed() {//if spaebar is pressed connect to arduino

if (key == " ") {

// important to have in order to start the serial connection!!

setUpSerial();//connect to arduino

}

}

function readSerial(data) {

if (data!=null){//if the data is not null

//////////////////////////////////

//READ FROM ARDUINO HERE (handshake)

//////////////////////////////////

wallstop= int(trim(data));

//////////////////////////////////

//SEND TO ARDUINO HERE (handshake)

//////////////////////////////////

let sendToArduino = movementLR + "\n";

writeSerial(sendToArduino);

}

}

function drawKeypoints() {

let totalX=0;//set variable to store the sum of the x coordinates of all the predictions

let totalY=0;//same for y

let avgctr=0;//set a counter to count the predictions

let len=0;//I dont use len here but i was experimenting somthing

for (let i = 0; i < predictions.length; i += 1) {

const prediction = predictions[i];

len=predictions.lenght*prediction.landmarks.length;

for (let j = 0; j < prediction.landmarks.length; j += 1) {

const keypoint = prediction.landmarks[j];

totalX+=windowWidth-map(keypoint[0],0,video.width,0,windowWidth);//map the points to our window size and sum it

totalY+=map(keypoint[1],0,video.height,0,windowHeight);

avgctr++;//increase this too

}

}

steerX=totalX/avgctr;//update steerX with the average of X

gearY=totalY/avgctr;//same for Y but with average of Y

}

function windowResized() {

resizeCanvas(windowWidth, windowHeight);//resize the canvas to go to fullpage

}

function keyTyped() {

// $$$ For some reason on Chrome/Mac you may have to press f twice to toggle. Works correctly on Firefox/Mac

if (key === 'f') {

toggleFullscreen();//if f is pressed, show fullpage

}

if(key==='q'){//if q is pressed go to h=intro page

if(introbool==false){

introbool=true;

introp.playbool=false;

S2.play();

}

}

// uncomment to prevent any default behavior

// return false;

}

// Toggle fullscreen state. Must be called in response

// to a user event (i.e. keyboard, mouse click)

function toggleFullscreen() {

let fs = fullscreen(); // Get the current state

fullscreen(!fs); // Flip it!

}

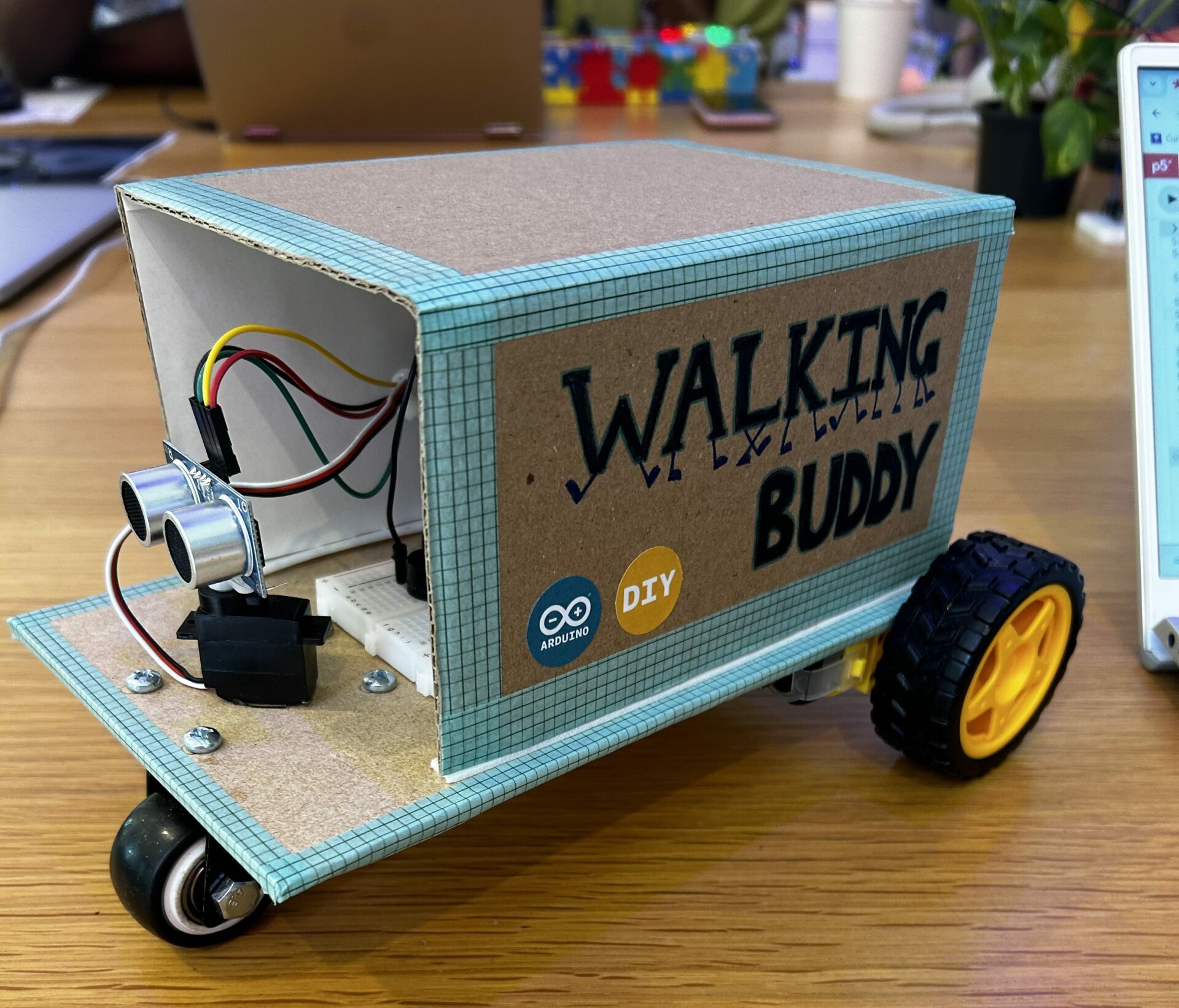

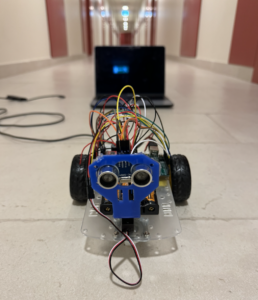

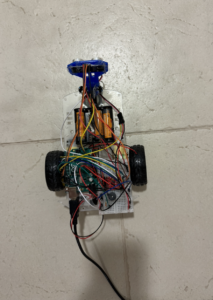

Rekas Bot:

My inspiration for this project comes from my zeal to use the ml library in p5 and I had fun developing this.

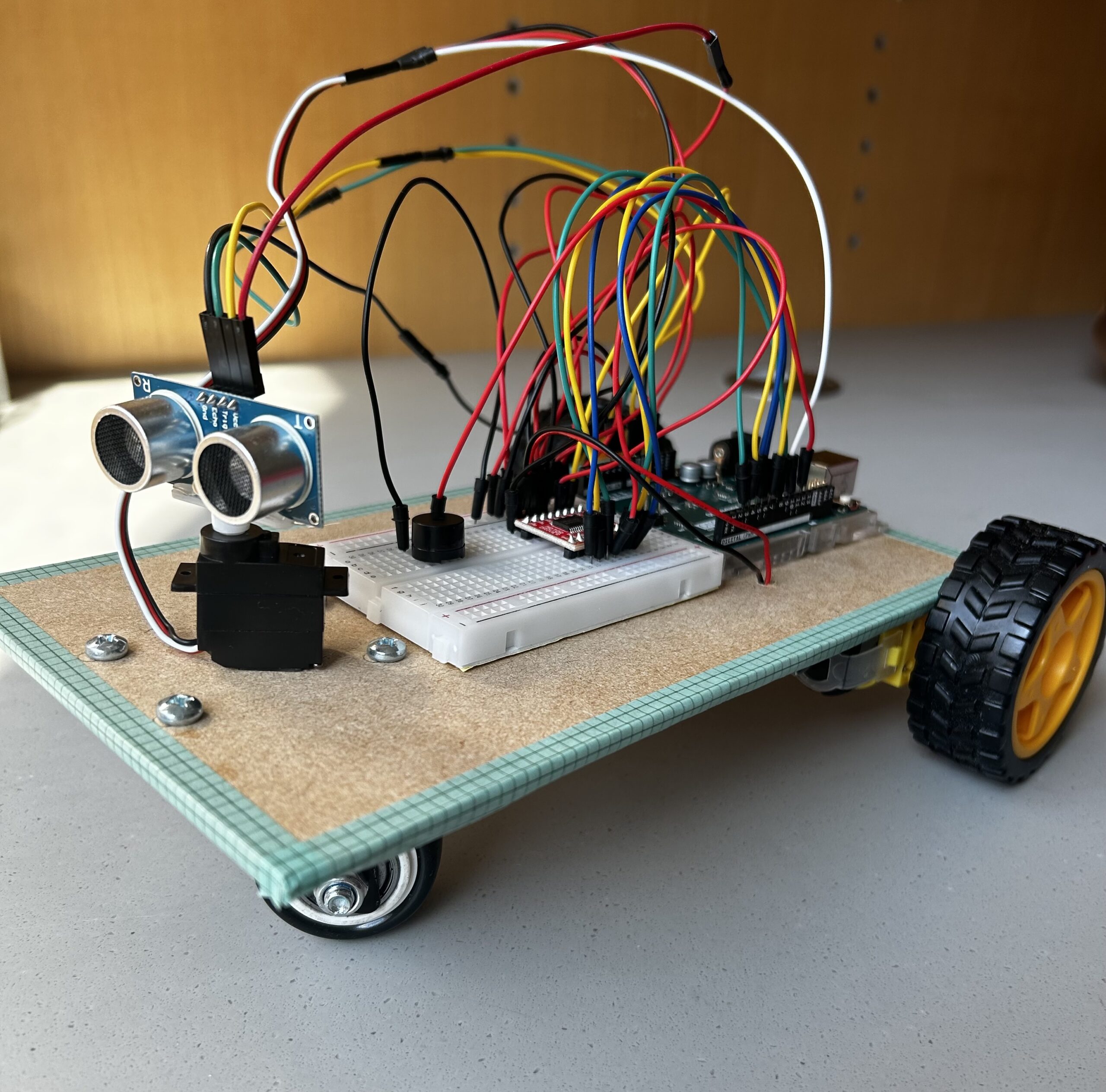

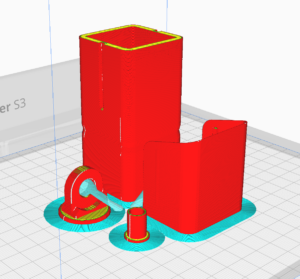

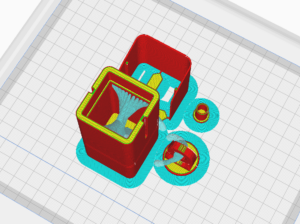

Model:

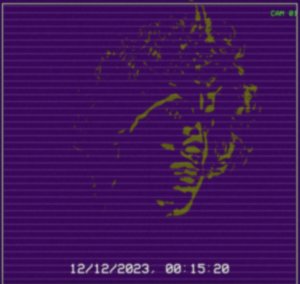

Test Video:

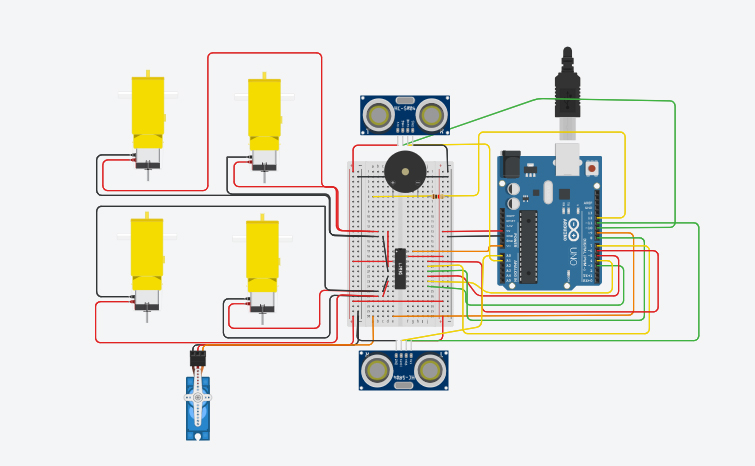

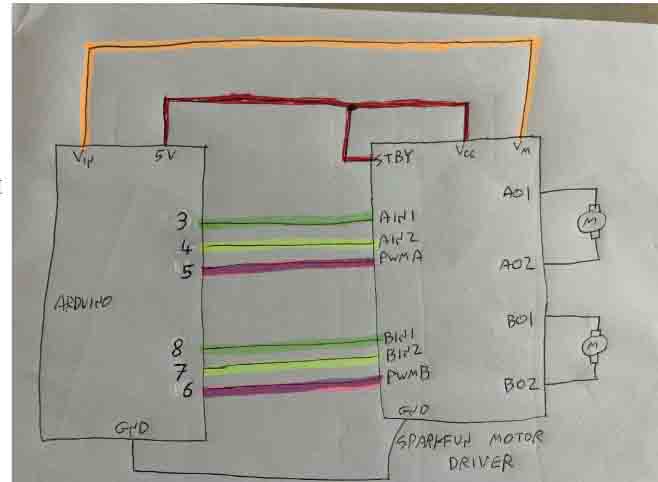

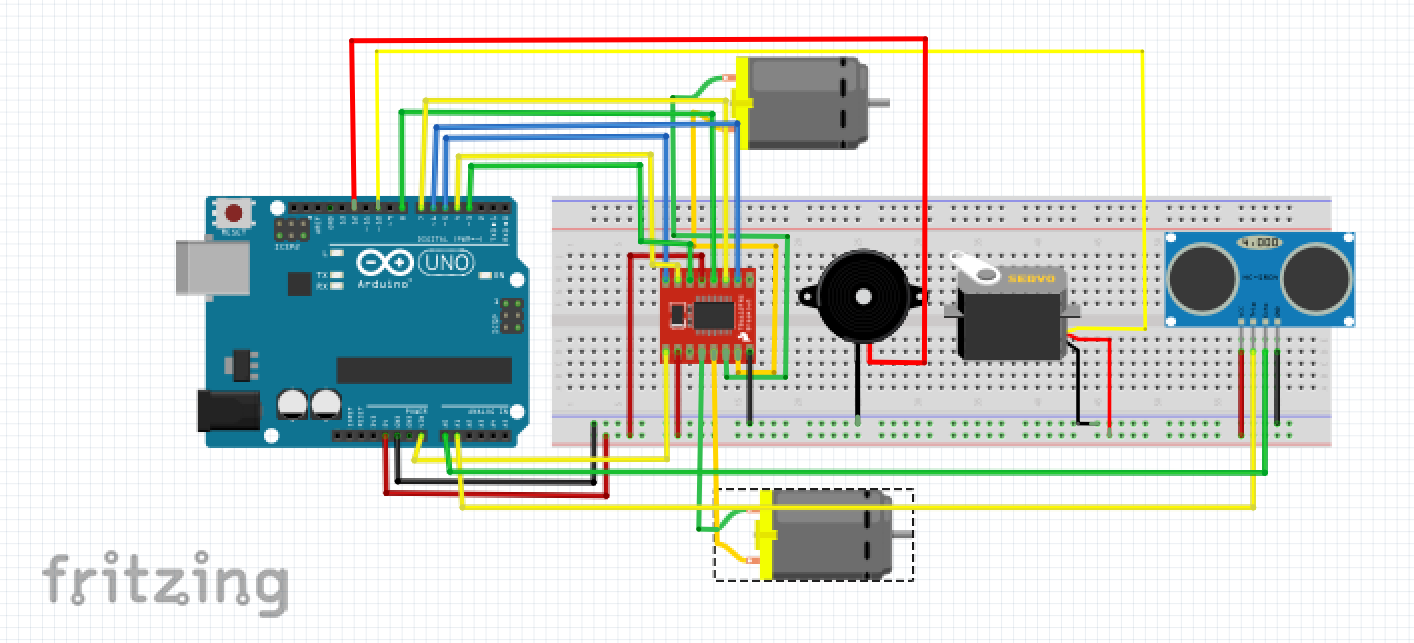

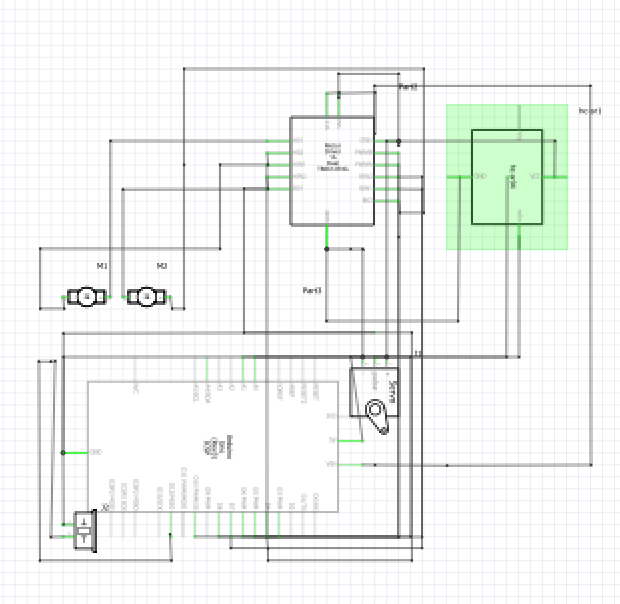

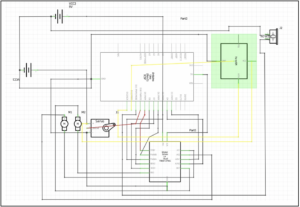

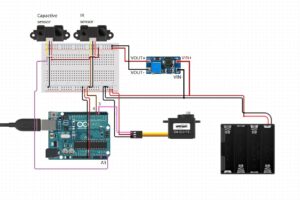

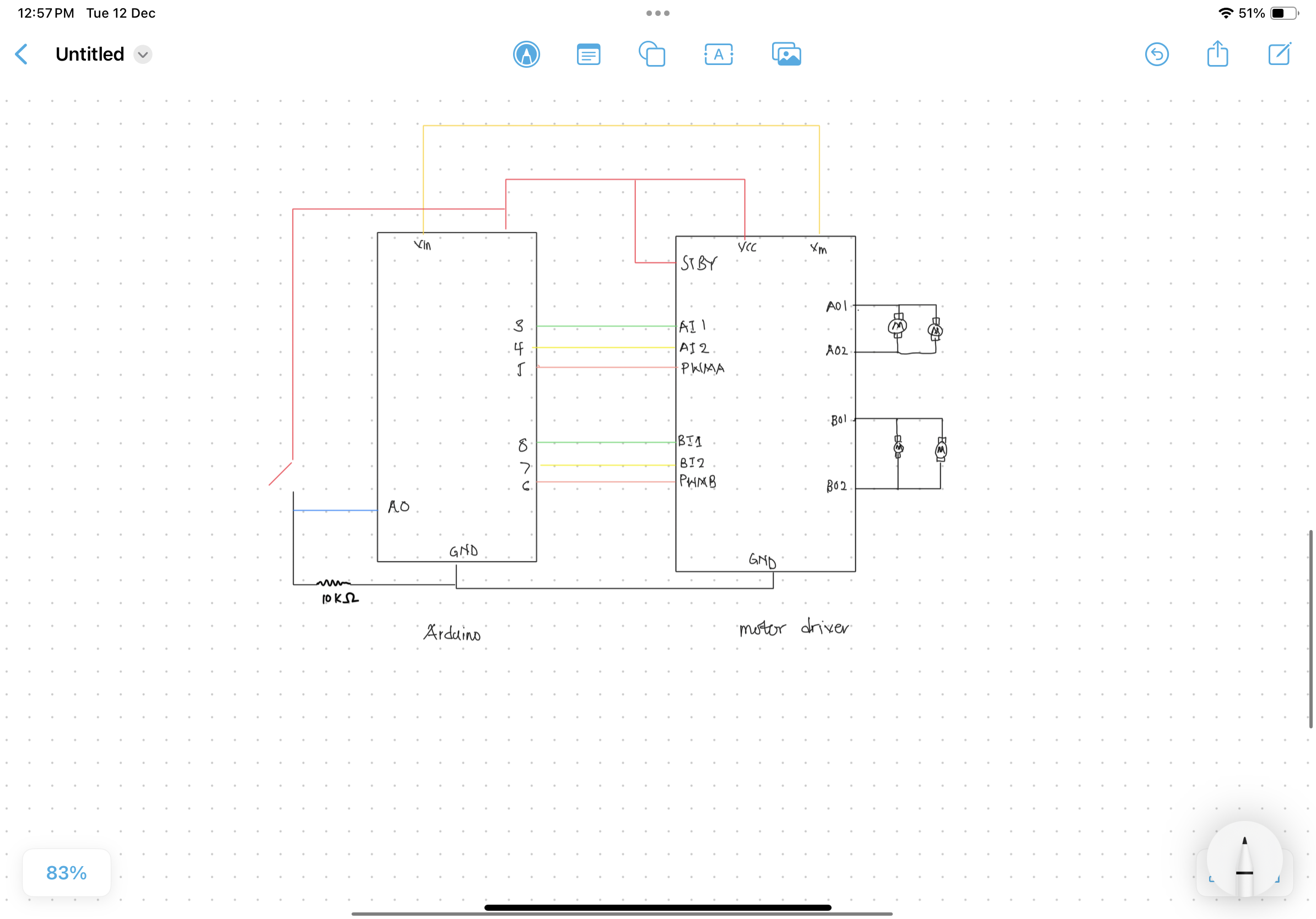

Arduino Circuit Diagram:

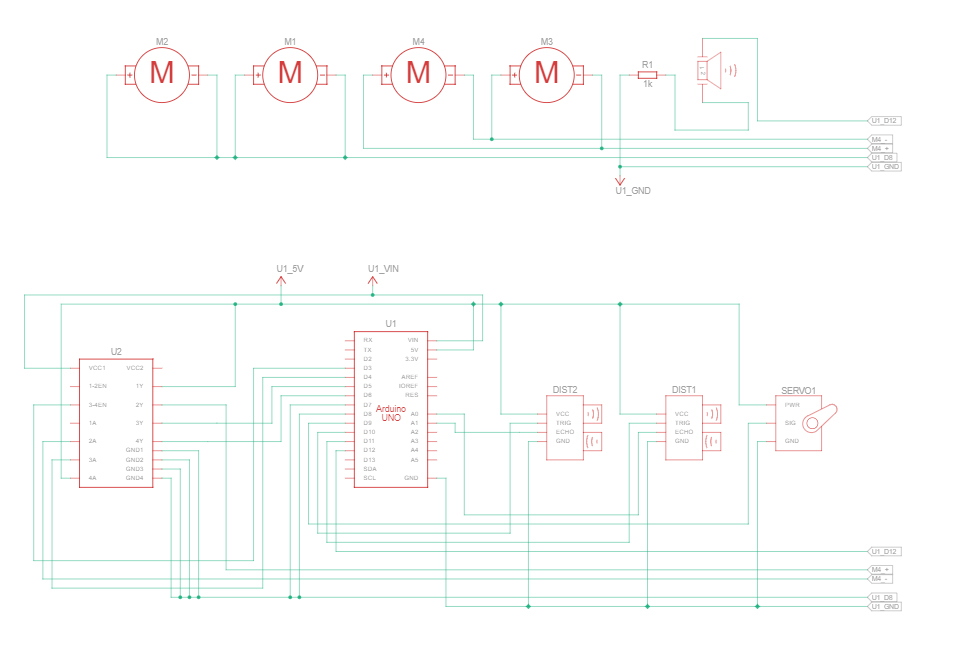

Schematic Diagram:

Clarification on the Schematic motor drawing:

By Aya Riad

By Aya Riad

Future Improvements:

I Tried to implement Bluetooth but I was not able to because it kept on failing even though I had connected and set up everything right so I wish to be able to find a way to make this connection more reliable and also I plan to make the machine learning more reliable in future.

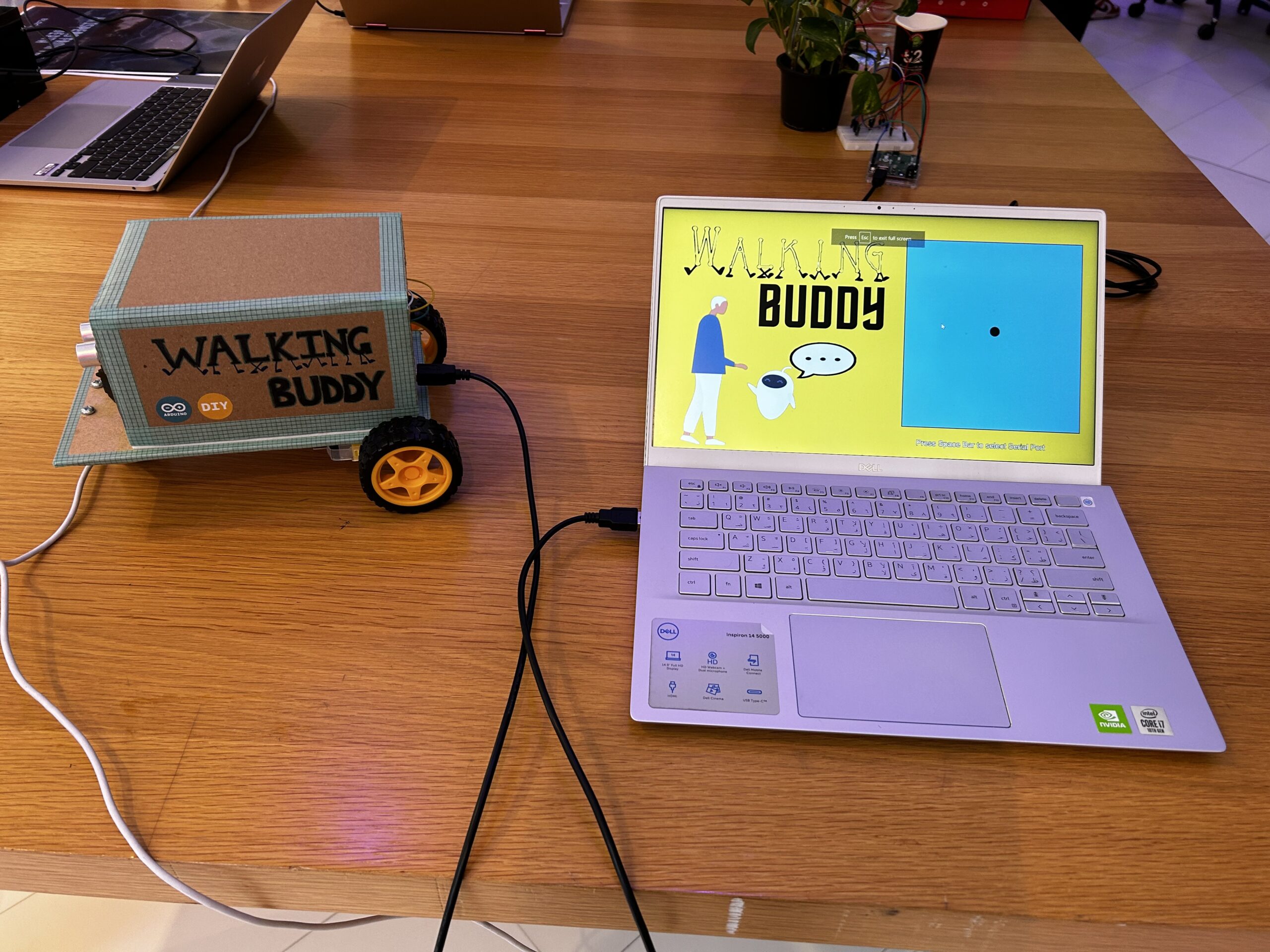

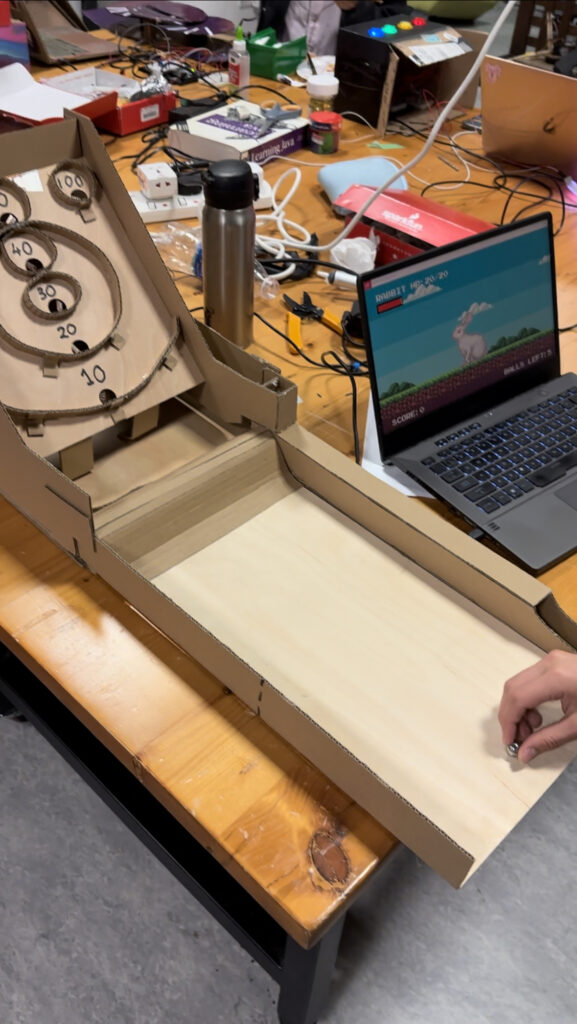

IM Showcase:

So just before the showcase started, I added one line of code which made the bot move randomly as though it had life.

if(introbool){//if the introbool is true show intropage

gamebool=introp.show();//update gamebool from intro.show function

movementLR=int(random(0,6));//do random stuff

if(gamebool){introbool=false;}//if the gamebool is true,set intro to false

}

I am really proud of this last decision.

and when you want to drive it, it stops the random movements.

For more videos

Thank you.

p5.js battle!

p5.js battle!

By Aya Riad

By Aya Riad